PRODUCTS SERIES

Table of Contents for This Page

It is not easy to introduce all aspects of WPC composite products, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

KR Company Profile

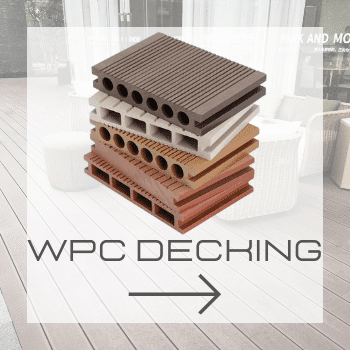

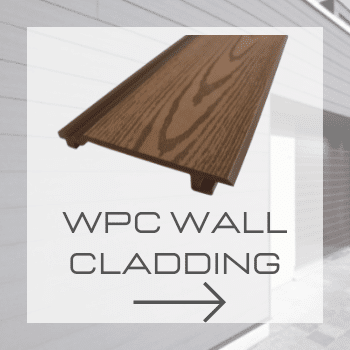

The company mainly produces: WPC normal decking, WPC 3D hollow decking, WPC normal wall cladding, WPC privacy fence . These products have passed CE, FCS certification and various industry tests for fire and heat resistance.

Our Advantage

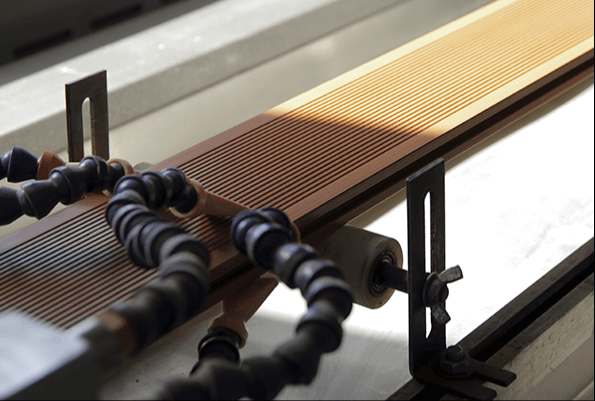

Production process of wood-plastic products

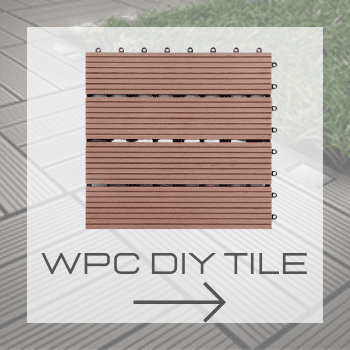

KR’s wood plastic products are environmentally friendly, waterproof and fireproof, UV resistant, and have a service life of 20 years or more. The main raw materials of WPC products are wood powder, high density plastic and chemical additives. Each WPC product has its own mold. Quality control throughout the whole production process.

The main raw materials of wood-plastic products are wood flour, high density plastics and chemical additives. Each wood-plastic product has its own mold. When the raw materials are mixed with pigments, the raw materials can be extruded from the mold by high-temperature extrusion machine. At room temperature or cold water, the products can be cooled and shaped. According to different appearance requirements, the surface of wood-plastic products can present patterns or polished grooves. Wood-plastic products can be customized in color and length, which makes wood-plastic products more popular in the building materials market. You can come up with your ideas and have KR customize everything for you.

RAW MATERIALS

The main raw materials of wood-plastic products are wood flour, high density plastics and chemical additives. So this building material is 100% recycled and eco-friendly.

MOLD ONLINE

Each wood-plastic product has its own mold. Until now, KR-WPC have around 340 molds of difference products. Also we can provide custmer with customized mold.

EXTRUSION

When the raw materials are mixed with pigments, the raw materials can be extruded from the mold by high-temperature extrusion machine. At room temperature or cold water, the products can be cooled and shaped.

SURFACE & LENGTH

According to different appearance requirements, the surface of wood-plastic products can present patterns or polished grooves. Wood-plastic products can be customized in color and length, which makes wood-plastic products more popular in the building materials market.

PACKAGING & LOADING

Different item materials will use wooden pallets at different lengths, which is more convenient for loading and unloading. International shipping usually uses container loading, 20GP and 40HQ are the most commonly used container types.

APPLICATION

Because WPC materials are environmentally friendly and can instead of wood, many countries around the world will use wood-plastic materials in most areas of outdoor buildings. Such as WPC decking, WPC wall paneling, WPC railing, WPC table, WPC chair, WPC pavilion and WPC fencing, etc.You can come up with your ideas and have KR customize everything for you.

Hot Selling

Cost Components and Price Range of WPC Products

As we all know , The main components of wood plastic composite products are 60% wood fiber , 30%HDPE , 10% chemical additive .

1- 60% WOOD FIBER

Wood flour for wood plastic material can be divided into poplar wood flour, bamboo wood flour, engineered wood flour, etc. We usually use a combination of poplar wood flour and engineered wood flour, adding these wood flour can make the wood plastic products brighter in color, and have high strength and water resistance. The Price range for such fiber is around :

2- 30%HDPE

The plastics used in wood plastic materials are generally recycled plastics (plastic shopping bags, mineral water bottles, etc.), recycled engineering plastics, and bio-recycled plastics. When the bio-plastic is added in a certain ratio, it can maintain the density balance of wood-plastic products, which will have better waterproof performance when used outdoors and prevent bending and cracking after exposure to the sun. Price range :

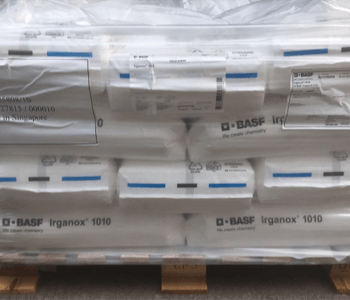

3- 10% chemical additive

Wood plastic materials are added with high-tech chemical additives to achieve better outdoor long-life performance. For example, flame retardant, anti-fading agent, preservative, insect repellent, these additives allow WPC products to prevent the spread of fire, outdoor use without fading and decay, and the use of no maintenance. KR special use of antioxidants imported from Germany, which allows the outdoor wpc flooring products in high temperature areas cracking and bending phenomenon is controlled. Price range :

APPLICATION

KR-WPC specializes in the production and innovation of wood plastic products for more than 8 years . At present, we have supplied to 24 countries and regions, such as UK, Argentina, Australia, Korea, Brazil, Czech Republic, Denmark, Saudi Arabia, Netherlands, etc. On the right side are some pictures of the projects completed with KR-WPC products. WPC products combine beautiful and natural styles. From flooring to fencing to every outdoor area, KR builds very functional and stylish outdoor living spaces that are environmentally friendly.

CUSTOMIZATION

1. Color

KR has 10 regular colors for you to choose, if these 10 colors are too common, you can tell KR’s sales manager the Pantone color number of the color you want, and our engineers will customize your exclusive color according to your requirements.

2. LENGTH

The length of wood plastic composite products can be cut at will, when you tell KR sales your length requirement, we will do it before packing the goods according to your length requirement, when you receive the goods, you can use it directly. If you purchase a container of goods, our recommended lengths are 2m, 2.2m, 2.4m and 3.6m and 5.8m.

3. MODEL

KR currently has 335 WPC molds, which can produce 335 models of WPC products. We have a research and development team that introduces new models every quarter to keep up with the changing market. Please feel free to contact KR when you have any ideas about new models, our team will turn your ideas into reality and use our experience to help you promote and sell.

FAQ

DOWNLOAD INFORMATION

If you want to know more information about WPC products and testing reports, please click on the files below to download.

Or contact us directly by email. sales@kr-wpc.com

Catalogue

Catalogue

Catalogue

Catalogue